Swedish Photonics ICT

Swedish Photonics ICT has a strong and long history driven by the large players Ericsson and the Swedish Telecom Operator, Telia, at an early stage focusing on and pioneering photonics, i.e. fibre optic communication systems and components.

Large research programmes, also supported by the Swedish government, have laid the ground for the Swedish Photonics ICT industry of today. Although these larger organisations have moved up the value chain, new smaller companies have emerged focusing in certain niche areas but covering altogether a whole value chain in the field from nano-electronics/photonics via components and high-speed subsystems to fully converged fixed/mobile networks including network management.

But the early large investments are still exploited today, not the least by companies like Infinera (previousy Transmode), Packetfront and NetInsight. All the component and subsystem R&D and manufacturing within photonics, which was part of both Ericsson and Telia, have been continued at a smaller scale by new companies. Nevertheless, the research driven by universities and institutes are strong in focused and somewhat narrow areas. However, each level in the value chain is represented in Sweden from component research to services delivered by ICT.

The areas listed below are the ones where Swedish research and industry have strong competence and are expected to continue to invest, covering the range from nano-electronics/photonics via components and high-speed subsystems to fully converged fixed/mobile networks including network management:

- High Speed Coherent Optical Communication

- Broadband Access, fixed and mobile

- Converged Mobile/Fixed Backhaul

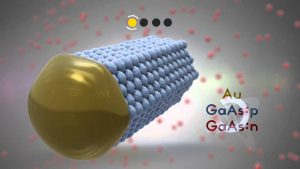

- Integrated- and Nano- Photonics, interconnect

- SDN, Software Defined Networks

- ”Green” Network Architecture

- National Testbeds, from End-user to Core

Companies active in photonics ICT

The early large investments mentioned above by Ericsson, Telia and the government are still exploited today, not the least by companies like Infinera (Transmode), Packetfront and NetInsight. The same is also valid for component and sub-systems companies like Proximion, Finisar Sweden (former Syntune), EXFO (TE Connectivity recently closed its Swedish subsidiary). Other companies active in Photonics ICT but not telecom-related are: Tobii (eye-tracking), Neonode (displays), Flatfrog (large displays)and Mycronic (displays and large area measurements).

Total turnover and total number of employees in the ICT segment are estimated to 2,2 billion SEK and nearly 700, respectively.

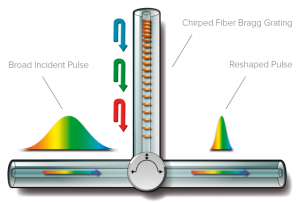

Introduction to ICT

Information and Communication Technologies are underpinned by optical broadband communication technologies. Obviously, neither internet, nor mobile communication would be possible without the use of optical fibres and the optoelectronic components required at their extremities. An optical fibre has an incredibly low attenuation around the wavelength of 1550 nm {3 times longer than green light). Imagine a one kilometre thick glass wall nearly perfectly transparent {can you notice 2% attenuation?). The use of optical transmission as close as possible to the mobile users does make a lot of sense, when energy needs to be saved at all levels, and it is very likely that so-called mobile cells will become smaller and smaller with strongly reduced radio powers and directional antennas. Optical fibres are anyway eventually coming to all our homes and the latter will probably be used as mobile cells.

Optical broadband technologies are also coming to the rescue of overheated data centres, where huge amounts of energy are consumed in cooling all the electronic equipment. Miniaturization of integrated optical circuits with strongly reduced power usage and fibre interconnections between racks will hopefully help to avoid that the ICT sector be soon using 20% of all electricity produced! The traffic volume is expected to continue growing by 10 times within 5 years or 100 times within 10 years as it has been doing during the last decades. Innovations will be required to make optical networks faster, greener, closer to the end-user, as well as more transparent, dynamic and cognitive.

The role of ICT for our society and for our socio-economic challenges is well known and it is not our role to describe them here. One more time, we would like to emphasize the fact that photonic technologies are the real enablers of modern ICT and contribute therefore explicitly to solving many societal challenges.

Industrial Manufacturing and Quality Control area in Sweden

Wood, paper and metal are important Swedish resources that can be processed further with clear added value instead of directly

exporting raw material from forest and mines. Lasers offer new design and processing possibilities and give many opportunities in creating new and exciting products for the world market. New jobs can be created and the society can gain increased prosperity. Many industries also introduce automatic quality control for achieving a better work environment; Manual inspection is often a cause for work injuries. Optics and vision systems controlling production processes and automatically inspecting/measuring/securing the quality of products is gaining more and more attention in manufacturing industries. Automation is a necessity for competitive mass production in European countries and automatic quality control is a key. The laser is a key element in obtaining a sustainable economy in Sweden and Europe. Innovative laser processes will play a significant role in the future green manufacturing as it provides a precise, well-controlled and highly effective energy deposition to the work piece. Future challenges are to increase the use of laser manufacturing technologies in all sectors where the laser can offer new product solutions, higher product qualities, and cost benefits. Major opportunities are in energy conversion, electronics, hybrid materials, light weight construction, rapid manufacturing, printing technology and product marking.

Swedish companies within process control and quality

OptoNova AB, Gedevelop AB, Innovativ Vision AB, Shapeline AB and Svensk Industriautomation AB are five Swedish companies with world-leading products for automatic inspection and quality control.

IKEA Industry Hultsfred produces more than 2 million wardrobes (called PAX) each year. The factory is running 24/7 with fully automated quality control with vison systems from OptoNova. All surfaces, edges, and holes are controlled on every furniture panel. Without automatic quality control this factory would have been set up in a low cost country according to IKEA management. Photonics enables cost effective production of consumer products in Sweden.

Research activities within Process control and quality

- KTH Royal Institute of Technology – Production engineering. Measurement and Optics.

- Luleå University of Technology– Experimental mechanics and wood technology – Optical measurement technologies in industrial applications.

- Swerea – Material and process development, Production engineering

- RISE:

- Acreo – Image sensors, fibre optic sensors and electro optic components

- Innventia – Research activities within paper and packaging. Including automatic inspection

- SP – Research activities within wood, glass, concrete, food, surfaces. Including optical metrology.

Introduction to Industrial Manufacturing and Quality Control

The competitiveness of industrial manufacturing relies heavily on the ability to increase productivity and quality assurance. The know-how and application of photonic principles using point sensors, 2D imaging, 3D imaging or spectral and other properties of light is a strategic tool in creating autonomous systems and faster in-line quality control systems in highly automated manufacturing. The whole automotive industry and traditional industry such as wood, paper, plastic and food as well as emerging industry benefits from using robotics and quality control of geometries colour and other parameters using light as a measurement principle. Future growth areas from the use of photonics in industry are machines for 3D-printing, recycling and robotics applied in autonomous transportation systems as well as in home or health-care applications.

For industrial applications, lasers are by far the most important photonic instruments, followed by vision tools and, increasingly also, by optical sensors. The laser tool enables to handling manufacturing processes automatically and flexibly with an extraordinary quality. The development during the last two decades of highly energy-efficient and high power, although tiny, ”lasing crystals”, more commonly called diode lasers, has also made laser machining much greener compared to other energy sources. Lasers allow for the machining of ultra-thin materials, e.g. in smart phones. They allow for cutting or soldering difficultly machined materials, such as the ones used to make lightweight and high- strength constructions for e.g. wind turbine blades. A number of instruments, increasingly important for our ageing population, such as pace-makers, synthetic bones, endoscopes and micro-cameras used for in-vivo investigations, are also enabled by laser machining. The next generation lasers will need to be more powerful, more intense (i.e. same power on smaller spots) and with other wavelengths outside the conventional visible and near-infrared regions. Other innovations will be required to deliver the laser light in a more versatile manner.

Life Science in Sweden: Sweden is the home of Carl von Linné and his cataloguing of the world’s flora. It is also the country of several very important innovations in the life sciences such as e.g. the pacemaker, the gel filtration chromatography, the hemodialysis, Losec® and the lidocaine. The dynamic environment found in Sweden is also part of the very important human proteome project and a famous researcher from the Royal Institute of Technology (also affiliated to SciLifeLab), Prof. Mattias Uhlén, is responsible for the Human Protein Atlas program with the ultimate goal to characterize the expression, localization, modification of all the human proteins. Several leading global Life Science companies have established themselves in Sweden. The organisation SwedenBio estimates that about 30,000 people work in around 800 companies in the Swedish Life Science which stands for around 20% of net exports. It is probably worth mentioning that the Karolinska institute (KI), which is also part of the SciLifeLab, is by far the highest ranked academic environment in Sweden. In the Time Higher Education world university ranking 2014-2015, KI is ranked 44 as a whole and ranked 8 (first in Europe) by QS World university rankings by faculty (Life Science and Medicine).

Life Science is a very important field for the largest regions of Sweden, before all the region of Stockholm-Uppsala region, but also Scania (Skåne) and the region of Gothenburg. Life Science is part of their regional strategies and in some cases integrated in the Smart Specialisation Strategy effort at the European level.

Swedish Biophotonics:

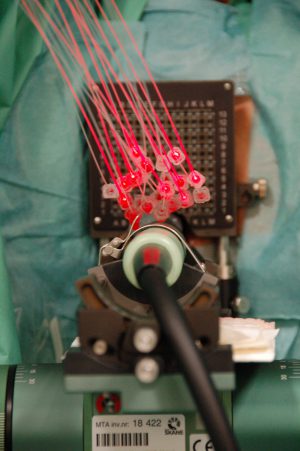

Photodynamic treatment of cancer prostata with a multi-fibre interstitial system developed by SpectraCure AB in Lund.

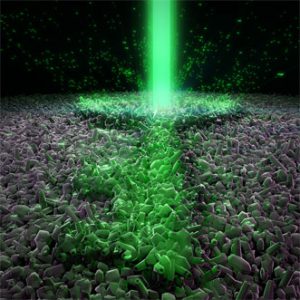

Biophotonics is a highly multi-disciplinary field involving physicists, chemists, engineers, as well as end-users in biology and medicine. Photonic methods and techniques are greatly contributing to solving several of the grand challenges of our time1: ”sustainable solutions in areas such as. water and food, ageing societies, public health, pandemics.”.

Optics and photonics are used in several fields of life science and health such as:

- Surgery and medicine {medical interventions).

- Diagnosis using imaging techniques and sensors.

- Biology and Biotechnology.

- Testing food and drug quality and safety.

- Agriculture (Smart Farming)

There are nearly 40 biophotonics companies in Sweden. In addition to these companies for which biophotonics is at the heart of their product, about 20 more companies also have an important activity in biophotonics. Most of the nearly 40 biophotonics companies are, or before acquisition by a large company, small- and medium-size enterprises (SMEs). Nearly all companies, even the large ones have seen their start in Sweden. The four largest companies are GE Healthcare Life Sciences AB, > 1600 employees among which about 200 work with biophotonics (which is based on the acquisition of Biacore AB by GE Healthcare in 2006), Philips Digital Mammography about 100 employees (Sectra Mamea acquired by Philips in 2011), Perten Instruments AB, about 250 employees (acquired by the American company Perkin-Elmer in 2014) and HemoCue AB, over 300 employees (presently owned by the Danish company Radiometer AS). The academic research and the collaboration with universities and institutes are at the origin of most, if not all, of these biophotonics companies. The couple Katarina and Sune Svanberg should have a particular mention here. Katarina and Sune Svanberg are both prominent researchers and professors from the university of Lund, Katarina in medicine and Sune in lasers and spectroscopy. They are, together with Prof. Stefan Andersson-Engels, at the origin of several companies (e.g. SpectraCure and GasPorOx) and of a very strong academic research in biophotonics (see the LMLC, Lund Medical Laser Centre). If a majority of the employees in the Swedish biophotonics companies are active in the application area medicine and healthcare, there is an incredible diversity of products from laser surgery and other kind of treatments to all sorts of diagnostic techniques.

Energy-Efcient Lightng and Displays

Light emitng diodes (LEDs) convert electrons into photons much more efciently than ordinary lamps. This combined with a smart optmisaton of how the light is used will lead to energy savings between 40 and 70% as compared to a contnued use of other types of light sources. LEDs give many new possibilites for lightng since the light comes from many small light points and the distributon of the light can hence be tailored very fnely. The spectral characteristcs can also be adjusted to a large extent, allowing for an adaptaton of the colour of the light at diferent tmes of the day. Smart lightng ofers very interestng business opportunites to several actors at diferent levels. Organic LEDs (OLEDs) are less mature than LEDs for lightng but open very interestng new opportunites. More distributed and fexible light sources can be realised with these. OLEDs are before all useful to make new types of displays. Energy-efcient displays can also be made with other types of LEDs.

Safety and Security

Safety and security aspects are very diverse from food to transpor- taton via explosives or air quality and in all these areas photonics brings or prepares solutons. For food safety, a major trend in Eu- rope is to look for proper sensors. One opton is develop a hand- held instrument based on mult-band IR sensing or imaging in an extended spectral range (from near-IR to far-IR, or 0.8 to 1000 µm). Optcal sensors are being developed to monitor the quality of combustbles for cars to avoid counterfeits. The requirements of improved isolaton in buildings make the monitoring of the air quality more and more important. CO detectors based on IR spectroscopy do the job very well. Metrology using 1.5-1.8 µm IR light is very eye-safe because the maximum permissible exposure is about 100 000 tmes larger than for visible or NIR bands. New extended IR systems promise to provide accurate fngerprintng of gases such as explosives. In additon, optcal techniques will allow for checking very large areas (or volumes) in a short tme. IR imaging is very useful for night vision in cars and other vehicles. 3D IR imaging, based on tme-of-fight measurements will allow for an efcient day vision with low interference with day light. Fi- nally, IR sensor could detect drugged or drunk driver on-the-fy even along motorways. Counterfeitng accounts for 5-7% of world trade every year (or about 500 billion Euros). Diferent optcal techniques are already commercialised or being developed based on extended IR to solve this problem. Civil engineering constructons or ships or airplanes can be equipped with sensors, either embedded already in the structure or installed aferwards, to monitor the mechanical resistance and possible failures before they might happen.

Metrology

Ultra-high precision provided by photonics in metrology can be illustrated with two famous examples. First, the atomic clock based on a cooled fountain. Caesium or Rubidium atoms are cooled by lasers and the hyperfne optcal transiton measured with ultra-stabilised lasers. Additonally, optcal combs are used for a convenient countng of optcal frequen- cies. The second example is the fbre optcal gyroscope which is the most powerful instrument to measure rotatons (at the level of 0.01 °C/h).

Defence

Let us cite the latest report on photonics of the US government : “There is virtually no part of a modern defence system that is not impacted in some way by optcs and photonics, even 2 2 “Optcs and Photonics, Essental Technologies for Our Naton”, Natonal Academy of Sciences, p. 80, 2012. 13 5 when the system is not optcally based. Modern defence systems are migratng toward optcally based imaging, remote sensing, communicatons, and weapons. This trend makes maintaining leadership in optcs and photonics vital to main- taining the U.S. positon in defence applicatons.” Europe, and not the least Sweden, is of course also very actve in this area. The defence industry is able to transfer tech- nologies developed for military applicatons to the civil sector. The defence industry’s experience in complex systems integraton, as well as combining and presentng data from sensors and databases in many ways is indispensable for the development of situatonal awareness systems for civil applicatons.

There are many facets of the so-called green photonics, optc and photonic technologies used for the generaton of energy, a beter control of the environment and a reducton of wastes. Some of them have already been described in 5.4.

Energy

Photovoltaic cells are used to generate electricity from the sun power. The energy generaton from photovoltaic cells has increased by a factor of 5 between 2007 and 2010 thanks to governmental incentves and one predicts that 12% of the European electricity will be produced in 2020 in this way. Cells fabricaton and extracton of charges are optmized by using laser machining. Fibre sensors and lasers are used to optmize the operaton and maintenance of wind turbi- nes. High power lasers are developed to generate ultra-small fu- sion reactors (laser fusion). Optcal fbres and optcal sensors are used to monitor currents and electric felds in electricity power plants and along high power lines. Distributed fbre sensors are used in hydroelectric dams to monitor strain and temperature.

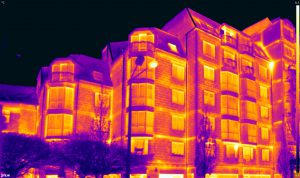

Environment Monitoring and/for Waste Reducton

An excellent example is given by the monitoring of house isolaton with infra-red cameras. The later give very nice pictures of the temperature distributon at beter than a tenth of a degree and thermal wastes due to bad isolaton, are very clearly identfed. Fibre sensors are used to monitor leakage of gas or liquids along pipelines. A very powerful technology for environment monito- ring is the so-called LIDAR (light detecton and ranging) which can map the concentraton of molecules (e.g. ozone in the high or low atmosphere, NO, CO or SO pollutants) over large volumes. Pulsed lasers can be focused on metallic scrap to generate a plas- ma which emits broadband light which will, afer spectral analysis, give its signature (laser-induced breakdown spectroscopy). This gives the possibility to automatcally sort out scrap for recycling.

Energy Efcient Communicatons

As mentoned earlier, optcal fbres makes informaton transport optmally energy-efcient. Less energy is lost per kilometre of transmission than any other medium. Obviously what needs to be done at the nodes and extremites of optcal fbre networks also has an important impact on the amount of energy used per transmited bit of informaton. The emergence of very compact photonic integrated circuits is very promising to make data centres less energy hungry. Another major improvement comes from the fact that more and more optoelectronic components do not need to be cooled anymore. Passive optcal components can do a lot of processing job that can replace a large amount of electro- nic circuits. Energy-efcient communicatons give more and more sense to teleworking to avoid unnecessary business trips and, why not, to avoid also quite ofen unnecessary commutng.

Clean Manufacturing

Laser machining allows reducing the amount of material waste. A big progress has also been made in the energy efci- ency of laser machining equipment. For example the frst welding lines for the automotve industry had an efciency of 3% whereas the same kind of lines today have an efciency of above 40%. The main improvements have been realised at the level of the laser sources with the upcoming of high beam quality diode lasers, single mode fbre lasers and kilo- wat class ultrafast lasers.